Systems Design

Planning and structuring of processes and facilities to optimise production efficiency and resource utilisation

Analyse and redesign workflows to minimise bottlenecks and streamline operations across manufacturing and assembly lines

Implement adaptable systems that can quickly respond to changes in product types, volumes, and demand

Develop models for effective allocation of resources like labor, materials, and machinery to meet production targets

Value Stream Mapping

Utilising value stream mapping to visualise, analyse, and improve workflow

Utilising visualisation tools that maps out all the steps involved in a process, from raw material acquisition to product delivery, enabling a clear understanding of the flow of information and materials

Applying lean methodology and principles Identifying waste, bottlenecks, and non-value-added activities within a process,

Helping teams and stakeholders understand the process flow, fostering collaboration and alignment

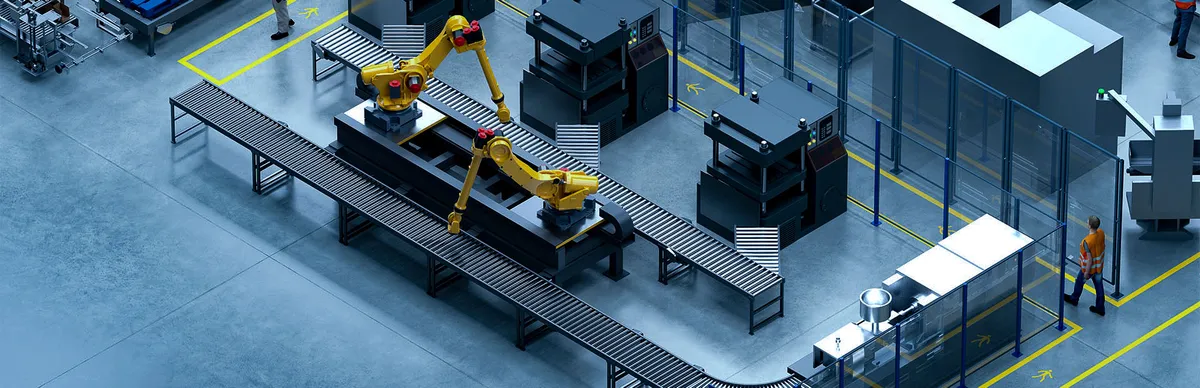

Facility Design and Layout

Optimising production lines and facilities

planning and arrangement of physical spaces, including buildings and work areas, to optimise workflow, efficiency, and safety

Arranging workspaces and equipment to create efficient workflows that minimize movement and reduce production times, enhancing overall operational efficiency

Designing layouts that maximize the use of available space

Incorporating ergonomic principles and safety standards in the design to create a secure working environment

Production Planning

Managing production schedules, resources, and workflows to meet demand efficiently and effectively

Implement JIT-JIS principles to reduce inventory levels while ensuring that materials arrive exactly when needed in the production process.

Create a detailed schedule that outlines what needs to be produced, when, and in what quantities to meet customer demands

Analyse production capabilities and forecast future needs andt resources

Work Measurement & Design

Evaluating and designing job tasks and work environments to improve efficiency, safety, and ergonomic performance.

Determine standard times for tasks using time studies and work sampling techniques to create benchmarks

Design workstations that promote ergonomic practices, increasing productivity

Create job roles that are clear and manageable, ensuring that tasks are aligned with employees’ skills

Supply Chain Management

Coordinating and managing all activities involved in sourcing, procurement, production, and logistics to deliver products

Implementing quantity methods and safety stock calculations to maintain optimal inventory levels without excess

Creating initiatives aimed at improving supplier performance through training, collaboration, and shared goals

Utilise forecasting and planning tools to align supply with expected demand, minimising overproduction and stockouts

Contact us

Created with

Instago